Safe and efficient storage of liquids in industrial sectors is of vital importance. To meet this need, stainless tanks are the guarantee of industrial storage and safety. Stainless tanks are widely used in industry. It is produced from stainless materials.

Usage Areas of Stainless Tanks

Stainless steel tanks are widely used in various industry sectors. These sectors include water storage, food (milk, olive oil, tahini, molasses), chemical (cosmetics), energy, petrochemical, pharmaceutical and many more. These tanks offer an ideal solution for the safe storage and transport of liquids.

Production of Stainless Tanks

Stainless steel tanks are manufactured using stainless steel and stainless steel sheet materials. Stainless steel and stainless steel sheet are known for their durability and resistance to corrosion. These properties ensure that the storage tanks are long-lasting and can be used safely in industrial processes. Seamless welds and high quality materials are used during the production of stainless steel tanks, which increases the durability of the tanks.

Advantages of Stainless Tanks

Stainless tanks have a number of advantages:

– Durability: The stainless steel material ensures long life and durability of the tanks.

– Hygiene: Stainless tanks offer a hygienic solution, which is important for the food and pharmaceutical industries.

– Corrosion Resistance: Stainless steel is resistant to chemical corrosion.

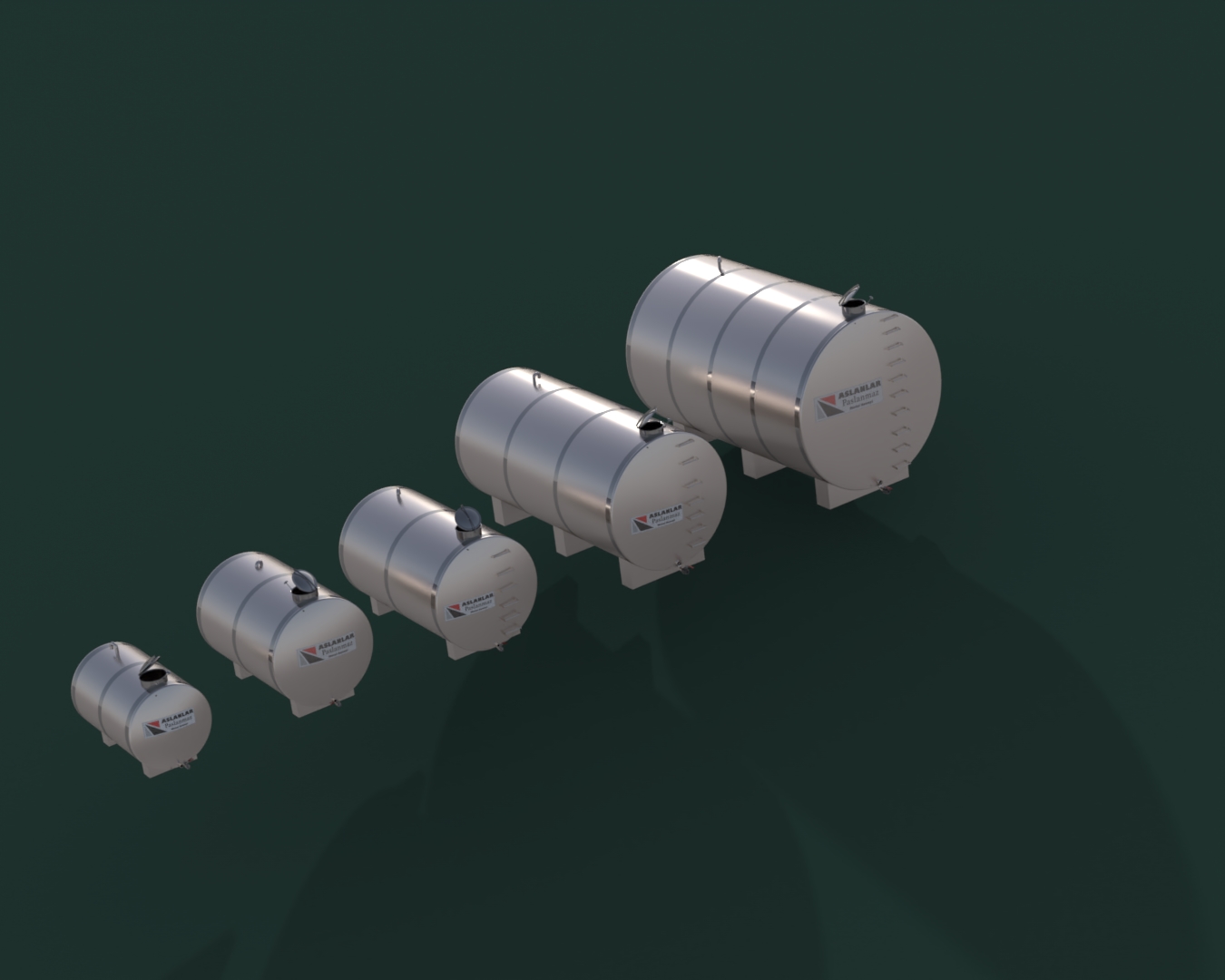

– Various Sizes: Stainless tanks can be manufactured in different sizes, which adapts to industrial needs.

Stainless tank are critical equipment that provide safe and effective storage of liquids in industrial sectors. Although stainless tanks are mostly preferred as water tanks, they are produced as storage products in the industrial field. Their durability, hygienic properties and wide range of uses ensure that these tanks ensure the smooth operation of industrial processes and the safe storage of products.